PDF(1968 KB)

PDF(1968 KB)

Potentiality evaluation of Pleurotus citrinopileatus cultivation with Tetradium ruticarpum branch sawdust

YE Jianqiang, ZHANG Fangfang, CHEN Lixin, HUANG Zhuozhong, LAN Taoju

Journal of Nanjing Forestry University (Natural Sciences Edition) ›› 2024, Vol. 48 ›› Issue (2) : 166-174.

PDF(1968 KB)

PDF(1968 KB)

PDF(1968 KB)

PDF(1968 KB)

Potentiality evaluation of Pleurotus citrinopileatus cultivation with Tetradium ruticarpum branch sawdust

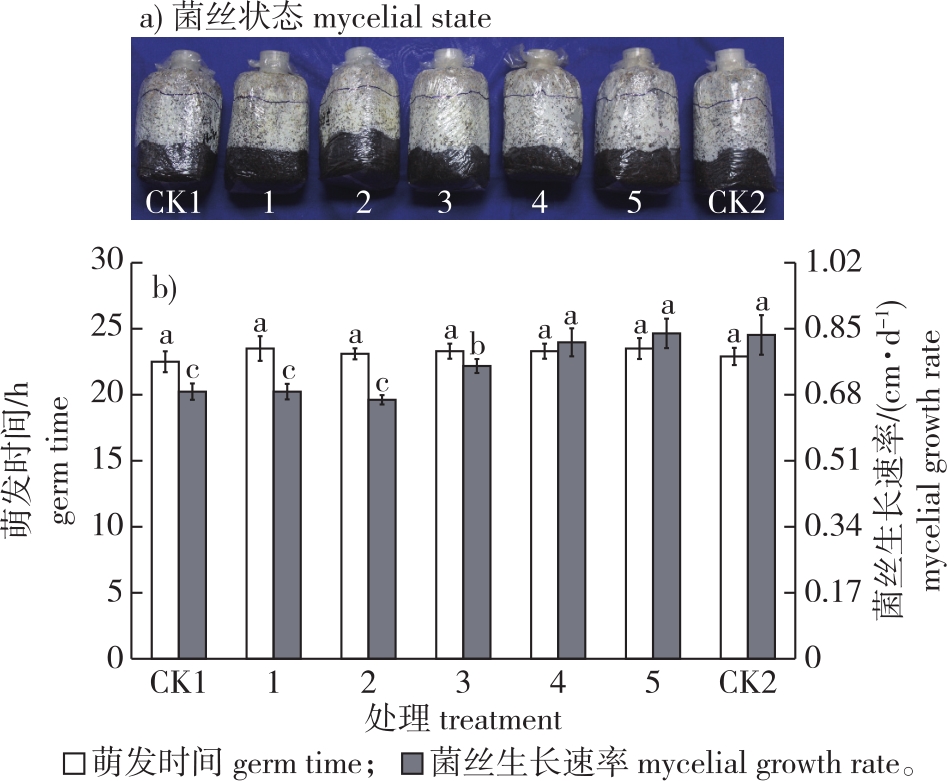

【Objective】 This study assesses the potential of using Tetradium ruticarpum branch sawdust for cultivating edible mushrooms. The research is significant for extending the T. ruticarpum industry chain and expediting branch degradation. It also offers a reference for efficient utilization of T. ruticarpum branches. 【Method】 The Pleurotus citrinopileatus, known for its short cultivation cycle, was chosen as the experimental strain. The nutritional content of T. ruticarpum branch sawdust, mixed wood sawdust and cottonseed hulls was analyzed. Tests involved replacing 20% (treatment 1), 40% (treatment 2), 60% (treatment 3), 80% (treatment 4) and 100% (treatment 5) of the mixed wood sawdust with T. ruticarpum branch sawdust. The effects on agronomic traits, fungus bag substrate degradation, and economic benefits in cultivating P. citrinopileatus were examined, comparing with the mixed wood sawdust (CK1) and cottonseed hulls (CK2) formulations. 【Result】 The cellulose, hemicellulose and lignin contents of T. ruticarpum sawdust were comparable to those of mixed wood sawdust (P>0.05), but its hemicellulose and lignin contents were 39.64% and 16.55% lower than those of cottonseed hulls. Its crude protein content was 4.25 times and 1.91 times that of mixed wood and cottonseed hulls, respectively. Its carbon-nitrogen ratio was 0.24 and 0.55 times that of the two. Selenium was not detected in mixed wood. Selenium content in T. ruticarpum sawdust was 7.69 times that of cottonseed hulls. Using T. ruticarpum sawdust increased inputs but had minimal impact on mycelium germination, growth and harvest times. It accelerated post-harvest recovery, significantly boosted yield, substrate utilization and economic benefits. Higher mycelial growth rates and fungus bag survival rates of 100% were observed in treatments 3,4 and 5, with no significant differences compared to CK2 in treatments 4 and 5. Biological efficiency was higher in treatments 2, 3, 4 and 5 than that of CK2, with treatment 4 yielding the best results. However, the total fresh weight was significantly lower than that of CK2. Fruiting rate higher than CK1 and CK2 was observed in treatments 3 and 4. Substrate degradation was the highest in treatment 4, with substrate utilization at 71.88%, cellulose degradation at 78.08%, hemicellulose degradation at 86.38%, and lignin degradation at 71.18%. Treatment 4 also showed the best economic performance, significantly better than CK1, and nearly equivalent to CK2, with only 0.03 yuan lower in profit per bag. It significantly reduced inputs and improved input-output ratio. 【Conclusion】 The T. ruticarpum branch sawdust is a material richer in crude protein and selenium than mixed wood sawdust and cottonseed hulls, and can replace pure mixed wood sawdust and pure cottonseed hulls for cultivating P. citrinopileatus. Replacing 80% of the mixed wood sawdust can guarantee a good survival rate of fungal packages and also a relatively high mycelial growth rate, yield, fourth flush yield rate, high material degradation and economic performance. It is a excellent edible fungi raw material, with a specific formulation of 62.4% (mass fraction, the same below) T. ruticarpum branch sawdust, 15.6% mixed wood sawdust, 20.0% wheat bran, 1.0% lime, and 1.0% gypsum.

Tetradium ruticarpum branch sawdust / P.citrinopileatus / cultivation of edible mushrooms / agronomic traits / substrate degradation / economic performance

| [1] |

|

| [2] |

王承南, 王红娟, 李平, 等. 不同产区三种吴茱萸有效成分的研究[J]. 中南林业科技大学学报, 2012, 32(8):86-89.

|

| [3] |

魏宝阳, 曹亮, 李顺祥, 等. 吴茱萸遗传多样性的AFLP分析[J]. 中国中药杂志, 2012, 37(3):278-282.

|

| [4] |

刘珊珊, 尹元元, 闫利华, 等. 吴茱萸药用植物资源调查[J]. 中国中医药信息杂志, 2016, 23(9):5-9.

|

| [5] |

南宁新闻网. 邕宁区新乐村:吴茱萸飘香农民喜开颜[EB/OL]. http://www.nnnews.net/p/3007758.html,2019-07-25.

Nanning News Network. Farmers were all smiles in the Evodia rutoecarpa harvest season of Xinle Village,Yongning[EB/OL]. http://www.nnnews.net/p/3007758.html,2019-07-25.

|

| [6] |

广西壮族自治区农业科学院. 广西农业科学院科技扶贫典型案例汇编[M]. 北京: 中国农业出版社, 2020:5-7.

Guangxi Academy of Agricultural Sciences. Compilation of typical cases of poverty alleviation through science and technology in Guangxi Academy of Agricultural Sciences[M]. Beijing: China Agriculture Press, 2020:5-7.

|

| [7] |

敖礼林, 敖艳, 周元, 等. 吴茱萸丰产高效栽培关键技术[J]. 科学种养, 2020,(2):21-24.

|

| [8] |

杨会书, 汤龙华, 孙兴旭, 等. 木腐菌保育实验初探[J]. 中国食用菌, 2016, 35(5):73-76

|

| [9] |

陈永娟. 香菇代料栽培技术发展动向[J]. 浙江食用菌, 1996(2): 3-5.

|

| [10] |

蔡武纯. 木屑栽培香菇[J]. 食用菌, 1980(1):49.

|

| [11] |

中国食用菌协会.中国食用菌协会关于印发全国食用菌2018年度产量、产值统计调查结果的函[OB/L]. https://mp.weixin.qq.com/s/ix9fCR9Wygz4rGfvAY7ypw,2020-03-19.

China Edible Fungi Association.A letter was printed and distributed concerning 2018 statistical survey results of yield and value of China edible fungi by China edible fungi association[OB/L]. https://mp.weixin.qq.com/s/ix9fCR9Wygz4rGfvAY7ypw,2020-03-19.

|

| [12] |

黄卫华, 陈明杰, 陈洪雨, 等. 葡萄枝栽培金顶侧耳及其营养成分分析[J]. 食用菌学报, 2019, 26(4):64-71.

|

| [13] |

杨笑然. 热带作物基质对3种侧耳营养利用及产量品质的影响研究[D]. 长春: 吉林农业大学, 2019.

|

| [14] |

张婧, 杜阿朋. 利用桉树木屑栽培榆黄蘑试验[J]. 食药用菌, 2017, 25(6):379-381.

|

| [15] |

|

| [16] |

郑安波, 郭莹. 玉米芯栽培榆黄蘑配方比较试验[J]. 食用菌, 2020, 42(6):37-38.

|

| [17] |

何达崇, 李槐, 戴圣生, 等. 桑枝杆栽培优质榆黄蘑成分分析[J]. 食药用菌, 2013, 21(5):290-292.

|

| [18] |

|

| [19] |

王雨琼, 周道玮. 白腐菌对玉米秸秆营养价值及抗氧化性能的影响[J]. 动物营养学报, 2017, 29(11)4108-4115

|

| [20] |

石娇蕊. 降解木质素菌株筛选及玉米秸秆多菌种发酵条件优化[D]. 长春: 吉林大学, 2008.

|

| [21] |

中华人民共和国国家卫生和计划生育委员会, 国家食品药品监督管理总局.食品安全国家标准食品中蛋白质的测定:GB 5009.5-2016[S]. 北京: 中国标准出版社, 2016:1-3.

National Health and Family Planning Commission of the People's Republic of China,China Food and Drug Administration. Determination of protein in foods of National food safety standard[S]. Beijing: China Standard Press, 2016:1-3.

|

| [22] |

熊素敏, 左秀凤, 朱永义. 稻壳中纤维素、半纤维素和木质素的测定[J]. 粮食与饲料工业, 2005(8): 40-41.

|

| [23] |

中华人民共和国农业农村部. 有机肥料:NY/T525-2021[S]. 北京: 中国农业出版社, 2021:7-9.

Ministry of Agriculture and Rural Affairs of the People's Republic of China. Organic fertilizer[S]. Beijing: China Agricuture Press, 2021:7-9.

|

| [24] |

中华人民共和国国家卫生和计划生育委员会, 国家食品药品监督管理总局.食品安全国家标准食品中硒的测定:GB 5009.93-2017[S]. 北京: 中国标准出版社, 2017:7.

National Health and Family Planning Commission of the People's Republic of China,China Food and Drug Administration. Determination of selenium in foods of national food safety standard[S]. Beijing: China Standard Press, 2017:7.

|

| [25] |

中国食用菌协会.2019年度全国食用菌统计调查结果分析[OB/L]. https://mp.weixin.qq.com/s/uJgpEP5sG3-lf2ebgbWrcg,2020-12-22.

China Edible Fungi Association.Analysis of 2019 statistical survey results of China edible fungi[OB/L]. https://mp.weixin.qq.com/s/uJgpEP5sG3-lf2ebgbWrcg,2020-12-22.

|

| [26] |

梁连友. 渭北苹果枝条栽培袋料香菇技术研究与推广[D]. 杨凌: 西北农林科技大学, 2006.

|

| [27] |

陈丽新, 黄卓忠, 韦仕岩. 葡萄枝营养成分分析及栽培秀珍菇试验[J]. 中国食用菌, 2010, 29(6):28-29.

|

| [28] |

王谦, 卢红, 王路遥. 荆条基质下毛木耳培养条件优化[J]. 北方园艺, 2017(12):146-150.

|

| [29] |

孙波, 周洪英, 吴洪丽. 桑枝栽培食用菌研究进展[J]. 食用菌, 2015, 37(4):5-7.

|

| [30] |

林金盛, 宋金俤, 陈余红. 利用桑树枝桠栽培香菇试验[J]. 食药用菌, 2014, 22(1): 53-54.

|

| [31] |

李志刚, 陈霞娜, 丁李春, 等. 适宜葡萄枝屑栽培的香菇菌株筛选[J]. 食用菌, 2022, 44(1):21-23.

|

| [32] |

李海铭, 张萌, 李兴, 等. 秸秆微生物降解的研究进展[J]. 山东化工, 2021, 50(9):70-72,74.

|

| [33] |

刘林峰, 何建清, 张格杰, 等. 园林废弃物木质纤维素降解大型真菌的筛选及能力研究[J]. 高原农业, 2021(3):249-255.

|

| [34] |

吴桐, 贾锐鱼, 路强强, 等. 白腐菌在木质纤维素酶解中的研究进展[J]. 江苏农业科学, 2021, 49(5):38-45.

|

| [35] |

王彩荣, 李田春. 金顶侧耳降解基质能力的研究[J]. 辽宁农业科学, 1994(3): 27-28+16.

|

| [36] |

李楠. 吉林省黑木耳优质高效栽培技术的研究[D]. 长春: 吉林农业大学.

|

| [37] |

张理堂, 肖兴云, 黄瑞贤, 等. 长白山区金顶侧耳栽培品种(系)比较试验[J]. 吉林蔬菜, 2018(4):43-44.

|

| [38] |

黄丹莲, 曾光明, 胡天觉, 等. 白腐菌应用于堆肥处理含木质素废物的研究[J]. 环境污染治理技术与设备, 2005, 6(2):29-32.

|

| [39] |

|

| [40] |

司徒成, 余天华, 宋宇欣. 不同食用菌对猕猴桃枝木质纤维素降解的比较[J]. 北方园艺, 2022(5):111-118.

|

| [41] |

陈国龙, 秦延春, 卢玉文, 等. 不同培养料对秀珍菇生长发育及主要营养成分的影响[J]. 食用菌, 2018, 40(6):33-34,49.

|

| [42] |

杨士锋, 张健, 刘军鹏, 等. 应用灰色关联度法筛选香菇栽培料中柠条屑添加量[J]. 食用菌学报, 2017, 24(2):10-14.

|

| [43] |

中华人民共和国国务院. 国务院关于印发“十三五”生态环境保护规划的通知[J]. 中华人民共和国国务院公报, 2016(35):40-76.

The State Council of the People's Republic of China. Notice on the issuance of the national plan of the ecological environment protection for the 13th Five-Year Plan[J]. Gazette State Counc People's Repub China, 2016(35):40-76.

|

/

| 〈 |

|

〉 |